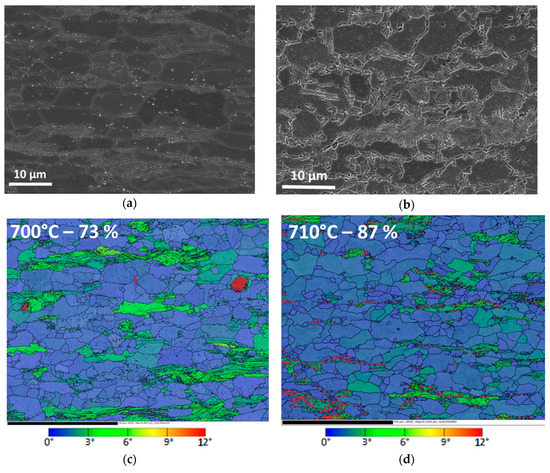

The phenomenon is demonstrated in equal-channel angular-pressed (ECAP) copper tested on the in situ system described. Through the use of in situ cryogenic experiments, it is demonstrated herein that stress-driven grain coarsening actually can occur at cryogenic temperatures. Cryogenic in situ micromechanical testing is a more recent capability, with only a handful of custom-built systems available. 16, 17, 18 In situ capabilities provide the ability to watch the deformation of the micro- or nanoscale specimen in real time, and also provide atmospheric control through the vacuum of the microscope. The system is a natural evolution of instrumented indentation with load and depth sensing 12, 13 that has enabled significant micro- and nanoscale mechanical testing across a wide array of applications 14, 15 and material properties. Furthermore, the system also enables orientation imaging microscopy to index electron backscatter diffraction (EBSD) patterns to characterize the microstructural evolution. The work presented herein fills this gap and provides direct proof of the phenomenon.Ī custom in situ, cryogenic, picoindenter system was built for use in a scanning electron microscope (SEM). Therefore, direct evidence of grain growth during deformation at cryogenic temperatures is still missing. As a result, coarsening could have occurred once the samples returned to ambient temperature. It could have occurred at the cryogenic temperatures, which is supported by the decrease in the indentation load at cryogenic temperatures 9, 10 However, it is also possible that the cryogenic temperatures simply prevented dynamic grain coarsening and encouraged the retention of the deformation energy in the system. Unfortunately, the ex situ nature of those experiments leaves some question about when the coarsening occurred. followed this work with similar ex situ indentation and characterization and demonstrated that the coarsening of different textures was correlated with the relative increase or decrease of specific grain boundary types namely, \( \left\langle \right\rangle \) nanotwinned Cu revealed a modest decrease in Σ3 content.

performed ambient and cryogenic indentation of nanocrystalline copper, followed by ambient-temperature ex situ characterization with a transmission electron microscope (TEM) of both samples interestingly, the observed coarsening was more dramatic for the sample indented at cryogenic temperatures. demonstrated in ex situ experiments that stress-driven coarsening may occur even at cryogenic temperatures. 1, 2 Stress has been demonstrated to be a driving force that biases grain growth under conditions where thermal energy would be insufficient, 3 a phenomenon that has attracted significant interest in recent years. Grain growth is an important mechanism for microstructural evolution, most often observed to occur at elevated temperatures where thermal energy facilitates diffusive boundary migration.

0 kommentar(er)

0 kommentar(er)